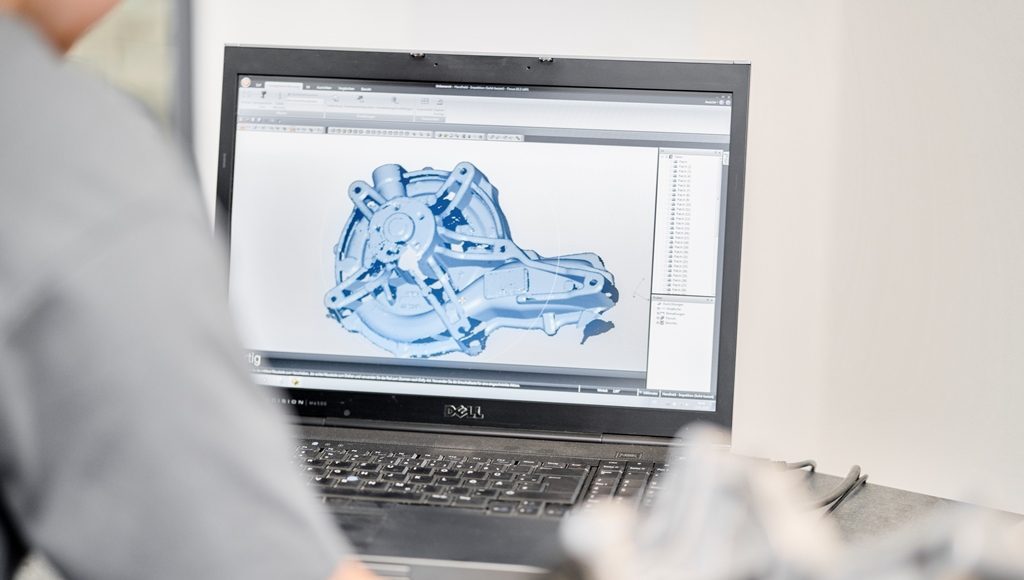

A glowing red line passes over the replacement part. The part is slowly scanned by the scanner and is completely measured as a result. A short time later, the article has become a 3D image in the computer – the laser scanner has made this possible.

The equipment was purchased just a few years ago for bilstein group Engineering. It is the prerequisite for so-called “reverse engineering”. Using this process, the production area of the bilstein group can first digitize car and commercial vehicle replacement parts and then manufacture them in its own production hall in identical or even higher quality.

The Smallest Details are Captured

In the first step, the already mentioned Nikon 3D laser scanner is used. With this powerful tool, the original part is thoroughly measured. An OE replacement part is always used as a sample. The device works within a tolerance range of 0.05 to 0.08 mm – an accuracy in which even the smallest details can be captured.

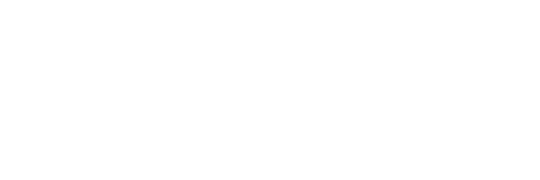

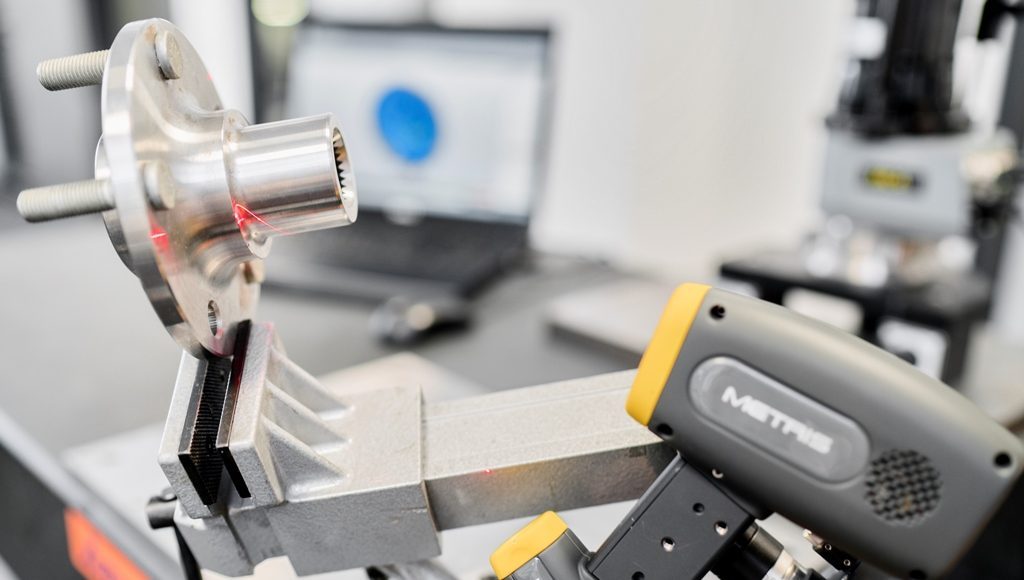

In less than three hours, the article is completely scanned. The data is then processed with a CAD program (reverse engineering) and processed into a design plan.

Pseudo Color Image Shows Any Deviation

Based on this, the next step is to produce an initial, low-volume batch of a few hundred blanks. Before further mechanical processing in production at bilstein group Engineering, the blanks are randomly inspected. The 3D scanner is used again to generate a pseudo color image of the inspected component. This allows deviations from the OE template to be detected directly.

If the quality control approves the quality, the blanks can be processed mechanically (milling, drilling, grinding, etc.). The engineering experts can rely on their decades of experience in metal processing as well as their modern machinery. Thanks to the scanner and the “reverse engineering” method, the result is a replacement part that meets exactly the same criteria as the OE product in terms of installation safety and quality.