Not all timing chains are the same: there are a variety of types that differ in shape and design depending on the requirements and load of the individual motors in which they are used. Here, we would like to introduce the most important ones.

Roller Chains

The roller chain is the most popular chain used and offers an ideal combination of strength and NVH performance. The inner link of a roller chain consists of two inner lobes, two sleeves pressed into the link eyes, and two rollers rotating above the sleeves.

Bush Chains

With the bush chain, the two rollers are dispensed so the sleeves are correspondingly enlarged in diameter and are directly engaged with the sprocket. Sleeve chains have a larger joint surface than corresponding roller chains. febi bush chains provide excellent strength and wear performance in high load conditions and are mainly used in fast running diesel engines.

Toothed Chains

The special design of this steel link chain is the toothed chain – also known as a silent chain. The middle and inner lugs are formed to provide exceptional transmission force between the chain and sprocket. febi toothed chains offer excellent NVH performance with enhanced durability characteristics.

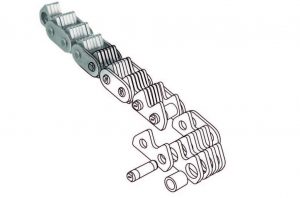

Combination of Toothed and Sleeve Chain

Due to their kinetic behaviour, toothed chains have a high potential for improving dynamic and acoustic properties. While toothed chain drives have been used for many years in lightly loaded timing chain drives, they have not yet been used in more heavily loaded engines due to the larger chain length compared to shell and roller chains.

In the new chain type of the toothed/sleeve combination, an optimized kinematic movement sequence at the inlet and outlet of the chain into the sprocket has made a reduced height of the inlet impulse possible. This also includes the non-uniformity of the movement and force transmission.

In order to improve the wear behaviour, a sleeve was integrated into the tooth lugs of the inner member. Whereas the articulation movement takes place at the inlet and the outlet into the sprocket between the tooth plate and the bolt in the case of conventional toothed chains, the process takes place between the sleeve and the stud in this chain variant.