The anti roll bar is a component of the chassis and connects the wheel suspension of an axle with the body structure. Many cars have an anti roll bar on the front axle, some of them also have them on the rear axle.

Anti roll bars have been used in passenger cars for decades and have been a virtually unchanged component ever since. Many motorists are unaware of the anti roll bar, although the replacement part makes an important contribution to safety and comfortable driving. The simple reason: without the anti roll bar, vehicles would tip over in a curve and driving straight ahead would be extremely uncomfortable. As a rule, even the rumbling noises from the chassis can be attributed to a defect in the area of the anti roll bar.

A failure of or damage to the anti roll bar is usually not expensive. This is attributable to the relatively low material costs and simple installation. But beware: if the anti roll bar is damaged, the vehicle should no longer be driven. The failure increases the risk that the rolling movements of the superstructure get out of control and the vehicle overturns.

Design and Function of the Anti Roll Bar

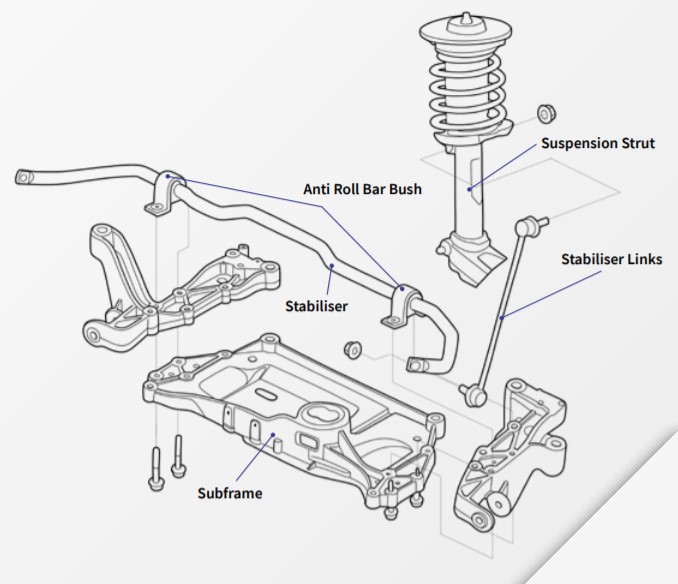

The anti roll bar includes other system components, e.g. coupling rod and anti roll bar bush. The anti roll bar is usually fitted to a subframe and mounted in rubber bearings. Double rods connect the anti roll bar to the suspension struts or alternatively to the control arms. Special ball joints on the coupling rods provide the necessary freedom of movement so the anti roll bar can perform its work flawlessly.

When one wheel is deflected, the torsion of the anti roll bar ensures that the other wheel is also raised and lowered when it is lowered. This prevents the body from swaying excessively (tilting sideways) when cornering. If both wheels enter simultaneously, the anti roll bar does not take action.

Symptoms of Failure

If the system fails or is damaged, strong rumbling noises often occur in the chassis when driving over bumps or potholes. In most cases, these are due to worn out bearings or defective ball joints of the coupling rods. If the bearings are worn out, there may be an unexpected play between the bearing and the anti roll bar. The anti roll bar may begin to rattle in the bearings during compression and deflection.

A very common type of coupling rod is equipped with ball joints which are protected against spray and external factors through a rubber boot. Furthermore, they contain a grease filling in order to allow for a smooth movement. From time to time, the rubber boots or the associated seals are damaged. As a result, water can penetrate and cause an unnaturally high level of wear.

The result: too much play in the joint leads to the sounds described above. The correct torque must be observed when mounting the coupling rod. Otherwise, the ball joint may be damaged and may wear out prematurely or even break off.